I wouldn't use wood screws for that kind of weight on a floating shelf (even with that nice ply backer). A floating shelf has a lot of leverage against that screw, trying to pull it outward, while other shelf types pull straight down with less lever action.

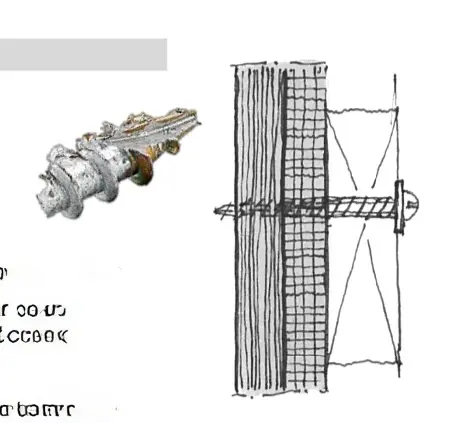

Use something like a toggle bolt or Molly. They distribute the load a lot more. I really prefer Molly for plaster/sheetrock, because they stay in place. Perfect for a floating shelf.

Edit: I hope the shelf has 3 or 4 mount points. That's still a lot of weight for just 2 screws with a floating shelf. I'd be concerned about the screw heads handling the load over time. They're probably fine, but it only takes one poorly made screw to bring the shelf down.