this post was submitted on 04 Mar 2025

17 points (94.7% liked)

Woodworking

6785 readers

55 users here now

A handmade home for woodworkers and admirers of woodworkers. Our community icon is submitted by @1985MustangCobra@lemmy.ca whose father was inspired to start woodworking by Norm and the New Yankee Workshop.

founded 2 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

Thanks for the info! Since I’m making the shelf, I can put more mount points so that should be no problem.

However - the problem with the Molly bolt things will be that the left half of the wall has space for a pocket door behind it so I’m worried that the toggle/molly bolts will get in the way of the door.

Maybe I should throw away the floating shelves idea…

Yea, the pocket door is a challenge, but there should be plenty of room - there should be a lot of space from the door to the ply panel. Once installed, a Molly should only extend about 1cm. Just make sure to cut the screw down once installed (the screw is longer so it can compress the Molly, easy to cut with a pair of dikes).

Optionally, you can use a wood screw for that end, one that's long enough to just go through the ply when set at the right depth. This will ensure you have maximum thread engagement.

Wood screws will probably be OK, it just makes me a little nervous with that weight. Of course, more screws=more distributed load, but then you have to get them all to line up perfectly, which isn't easy.

I think you’re right! I just checked and the pocket door is definitely much further behind.

Now the question is - how exactly do I use these to mount the shelf? Is there some sort of hidden bracket I can buy?

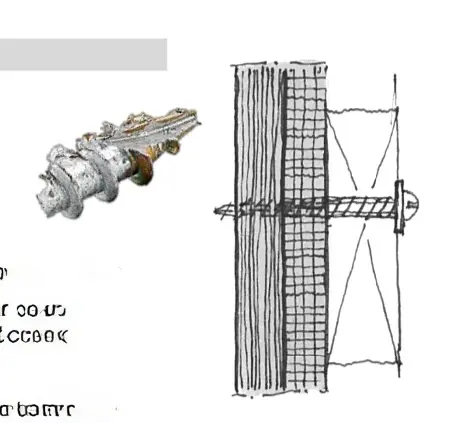

Lots of ways to do it, the most common I've seen are like this:

https://www.ultrashelf.com/collections/floating-shelf-brackets

Where holes are drilled into the shelves and then they're slid onto the rods screwed to the wall. Hard to level but looks great if done right

Wow, 50 lbs (~20 kg) per stud, with a bunch of screw holes in the base plate. Problem solved, and you could just use a number of wood screws into the ply panel, just spaced well apart (like 2.5-3 cm), and anchor into a stud where you can with a long lag (3"/~8cm).

Or if you can only hit a stud on one side, use a single Molly on the other and a couple wood screws in between.

yeah you may want some sort of "leg" running back to the wall, like a right triangle. that way the weight is not ONLY pulling straight outward, it has a a leg that presses back against the wall for support.