3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

Anyone aware if that be re-melted or recycled back into filament, or is it pretty much done for?

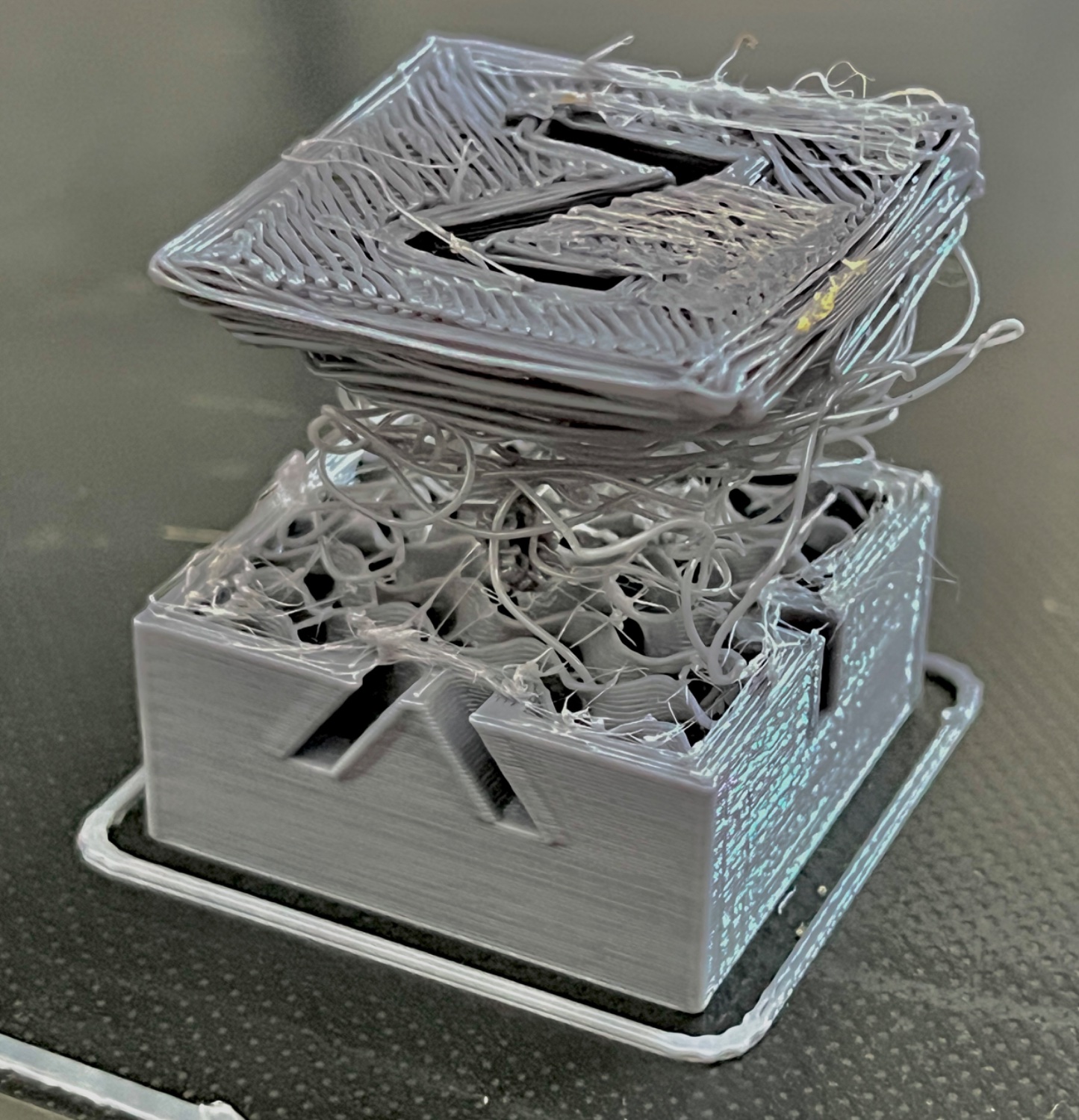

If I had a 3D printer this would be nightmare fuel after waiting X hours for the print to complete lol

In theory, you can remelt. Unfortunately, the practicalities mean it's not viable. Each remelt cycle degrades the plastic itself, so you can only put 20% or so 'old' plastic into the mix. Combined with the game of plasticisers (to remove brittleness) and reliable forming, even commercial systems struggle, let alone home ones.

If environmental concerns are the issue. It's best to print in uncoloured PLA filament. PLA is corn starch based, and decomposes in a bio reactor environment (it rots quickly in an industrial composter).

As for speed. They are getting impressively fast. A calibration cube takes around 20 minutes, though less than 5 minutes is possible. My machine is effectively fire and forget. They mess around while you are tuning them in, but once you have a good calibration, they now tend to hold it well. You'll sit there watching it in fascination for the first few months, but that wears off.

You kinda get used to them failing.

Part of the reason my printer just sits there not being used, aside from I collect hobbies for fun, is that it’s a nightmare levelling the bed and getting things dialled in.

Resin printers don’t have these issues but it depends what you’re printing I guess.

Get an automatic bed leveler.

My printer just sits there, covered. When I want something, I uncover it, clean the printing surface with some alcohol, and tell it to print.

By the way, resin printers have a completely different set of issues. But yeah, they don't have those ones.

I have a BLTouch. Perhaps I need to assess how sturdy it’s table is that it lives on.

I have one of those servo sensors that use a microswitch at the end.

The printer has a sturdy frame build from extruded aluminum. That probably makes a lot of difference. I can take the printer, move it into some other surface, turn it on and print, without leveling issues. Before it I had a wooden one without autoleveling. That one needed leveling before each print.

resin printers have the slight issue of being a chemical hazard and requiring PPE.

With resin when a print fails, you just get a half print stuck to the bottom of the resin tank, no spaghetti. The most common cause of failure is the part falling of the lifting platform, typical due to poor supports, but rarelybecause the platform is crooked.

Leveling is pretty easy on most printers, just loosen the bed, remove the resin tank, placing some thin cardboard in it's place, lower the platform until it touches the cardboard, and lock it in place.

Getting an auto leveler was a game changer for me. I still manually level the bed and check the Z offset every two months or so along with other maintenence, but I've gone on week long printing sprees without touching the bed springs once.

I have a BLTouch but still have issues. I do feel maybe a sturdy table is needed.

A few tips that made my prints much better:

I used to have a lot of problems with parts lifting up or my prints being unclean but since I did this my prints look great and stick to the bed.

Thanks for these tips. The next time I’m motivated to print something I’ll definitely take this on board.

You get used to that being a possibility with every print. That’s why you should do everything in your power to have your printer always in shape and operational, although sometimes it will happen no matter what!

Unfortuneatly, this is just waste, straight to the bin.