Hello, and thank you in advance.

I'm making a privacy friendly "ring" cam/doorbell following this guide: https://tristam.ie/2023/758/ which has been great, but requires running a micro-usb cable down to the doorbell for power. I'm hoping to improve on this by using the existing doorbell power instead.

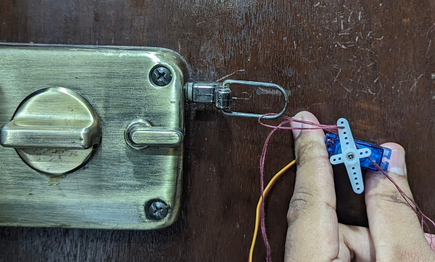

The problem is that I'm a DIY electronics noob and I can't create a mental model for how it should all work. The picture I attached is my existing doorbell wiring scheme, which is as simple as it comes. I totally get how this works. Pressing the doorbell completes the circuit and makes the bingbongs. But this will have to change so the new door cam gets power full time. Ideally without the chime bingbonging full time.

In addition to the ESP-32CAM, button, ring lights, etc., I also bought these: https://www.amazon.com/dp/B079FJSYGY which I thought might be needed to complete the circuit?

I measured the voltage after the transformer and it was around 18 volts, but maybe this is AC and I want DC?

Generally I don't know where in "the loop" to put things. Also, all the existing components are very far apart from each other, so I would love a solution that doesn't involve running any new wires through the walls.

Any help is appreciated. Thank you!!

xoJimbabwe